[JD] John Deere PowerTech 6068 6.8L Compressed Natural Gas Engine Repair Technical Manual CTM146

- Download this document, you need 1050 Gallons

John Deere PowerTech 6068 6.8L Compressed Natural Gas Engine Repair Technical Manual CTM146

Format: PDF

Language: English

Type of Document: Component Technical Manual

Type of Machine: PowerTech

Number of Pages: 485 pages

Part Number: CTM146

Model: John Deere 6.8L 6068 Repair Component Technical Manual

John Deere 6068CNG

Content:

Foreword

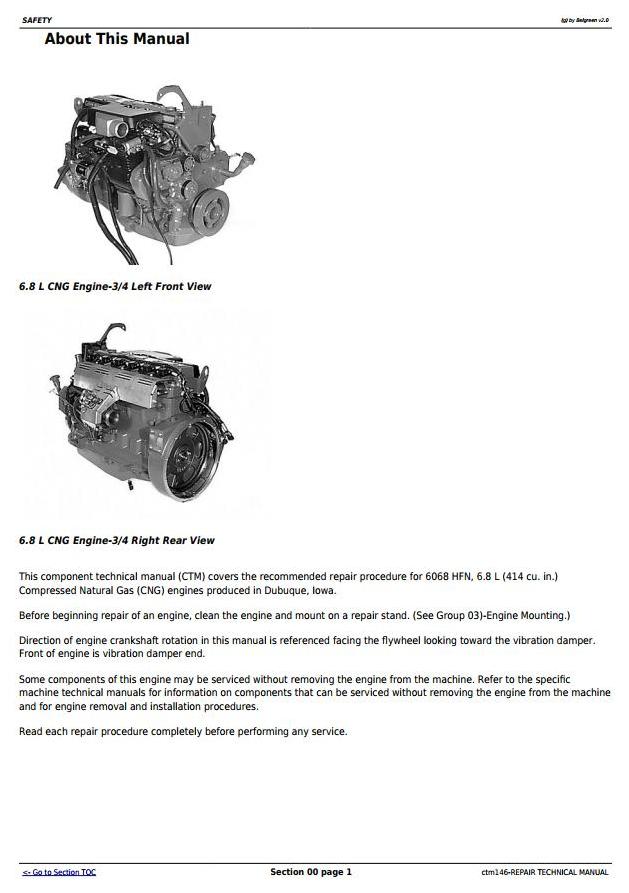

About This Manual

Safety

Handle Fluids Safely-Avoid Fires

Handle Natural Gas Safely

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Avoid High-Pressure Fluids

Wear Protective Clothing

Service Machines Safely

Work in Ventilated Area

Work in Clean Area

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Illuminate Work Area Safely

Use Proper Lifting Equipment

Practice Safe Maintenance

Use Proper Tools

Dispose of Waste Properly

Handle Compressed Natural Gas (CNG) Safely

Service Compressed Natural Gas (CNG) Systems Safely

Protect Against High Pressure

Protect Against Extremely Cold CNG Leakage

Live With Safety

General Information

Unified Inch Bolt and Cap Screw Torque Values

Metric Bolt and Cap Screw Torque Values

Engine Model Designation

Engine Serial Number Plate Information

Fuels, Lubricants, and Coolant

Natural Gas Recommendations

Natural Gas Engine Oil

Engine Break-In Oil

Alternative and Synthetic Lubricants

Mixing of Lubricants

OILSCANOILSCAN is a trademark of Deere & Company. and CoolScanCoolScan is a trademark of Deere & Company.

Grease

Recommended Engine Coolant

Engine Coolant Specifications

Testing Diesel Engine Coolant

Replenishing Supplemental Coolant Additives (SCA’s) Between Coolant Changes

Operating in Warm Temperature Climates

Flush and Service Cooling System

Disposing of Coolant

Engine Mounting

Engine Repair Stand

Safety Precautions

Install Adapters on Engine Repair Stand

Engine Lifting Procedure

Clean Engine

Disconnect Turbocharger Oil Inlet Line

Mount Engine on Repair Stand

Engine Mounted on Repair Stand

Engine Rebuild Guide

Engine Disassembly Sequence

Sealant Application Guidelines

Engine Assembly Sequence

Cylinder Head and Valves

Special or Essential Tools

Service Equipment and Tools

Other Material

Cylinder Head and Valves Specifications

Check and Adjust Valve Clearance

Measure Valve Lift

Remove Cylinder Head

Disassemble and Inspect Rocker Arm Shaft Assembly

Assemble Rocker Arm Assembly

Inspect, Measure, and Assemble Camshaft Followers

Measure Valve Recess in Cylinder Head

Preliminary Cylinder Head and Valve Checks

Remove Valve Assembly

Inspect and Measure Valve Springs

Inspect Valve Rotators

Clean Valves

Inspect and Measure Valves

Grind Valves

Inspect and Clean Cylinder Head

Check Cylinder Head Flatness

Measure Cylinder Head Thickness

Clean Valve Guides

Measure Valve Guides

Knurl Valve Guides

Clean and Inspect Valve Seats

Grind Valve Seats

Remove Valve Seat Inserts

Measure Valve Seat Bore in Cylinder Head

Install Valve Seat Inserts

Install Valves

Inspect and Clean Exhaust Manifold

Clean and Inspect Top Deck of Cylinder Block

Measure Cylinder Liner Standout (Height Above Block)

Install Cylinder Head and Cap Screws

Torque-Turn Method for Proper Torque

Install Rocker Arm Assembly

Inspect and Clean Ventilator Outlet Hose

Install Rocker Arm Cover

Complete Final Assembly

Perform Engine Break-In

Cylinder Block, Liners, Pistons, and Rods

Special or Essential Tools

Service Equipment and Tools

Other Material

Cylinder Block, Liners, Pistons, and Rods Specifications

Connecting Rods-General Information

Remove Pistons and Connecting Rods

Remove Cylinder Liners

Complete Disassembly of Cylinder Block (If Required)

Preliminary Liner, Piston and Rod Checks

Disassemble Piston and Rod Assembly

Clean Pistons

Visually Inspect Pistons

Clean Cylinder Liners

Visually Inspect Cylinder Liners

Check Piston Ring Groove Wear

Measure Piston Pin Bore

Measure Piston Skirt

Determine Piston-to-Liner Clearance

Deglaze Cylinder Liners

Replace Piston and Liner Sets

Inspect and Measure Connecting Rod Bearings

Inspect Rod and Cap

Inspect Piston Pins and Bushings

Remove Piston Pin Bushing

Clean and Inspect Connecting Rod Pin Bore

Install Piston Pin Bushing in Connecting Rod

Measure Rod Center-to-Center Bores

Inspect and Clean Cylinder Block

Clean Cylinder Liner O-Ring Bore

Measure Cylinder Block Main Bearing Bore

Measure Camshaft Follower Machined Bore in Block

Measure Camshaft Bushing Bores in Block

Measure Liner Flange Counterbore Depth in Block

Measure Liner Flange Thickness

Measure Cylinder Block Top Deck Flatness

Remove, Inspect, and Install Piston Cooling Orifices

Measure Cylinder Liner Standout (Height Above Block)

Install Packing on Cylinder Liner and O-Rings in Block

Install Cylinder Liner in Block

Assemble Connecting Rods onto Piston

Install Piston Rings

Connecting Rods-General Information

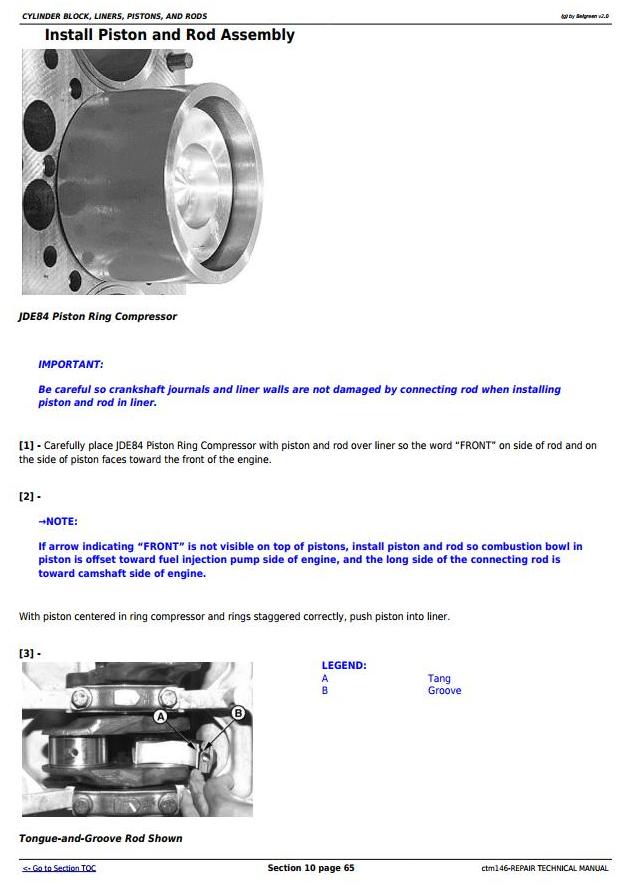

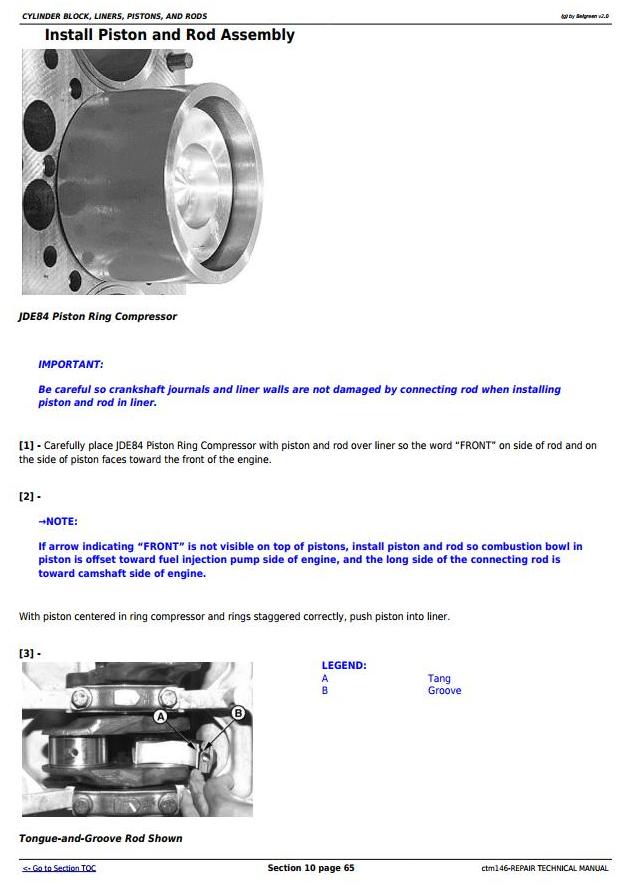

Install Piston and Rod Assembly

Torque-Turn Connecting Rod Cap Screws

Check Engine Rotation for Excessive Tightness

Measure Piston Protrusion

Complete Final Assembly

Crankshaft, Main Bearings, and Flywheel

Special or Essential Tools

Service Equipment and Tools

Other Material

Crankshaft, Main Bearings, and Flywheel Specifications

Crankshaft Grinding Specifications

Crankshaft and Main Bearing Failure Analysis

Inspect Vibration Damper

Remove Pulley or Vibration Damper and Pulley

Install Pulley or Vibration Damper Pulley

Checking Vibration Damper or Pulley

Replace Front Crankshaft Oil Seal and Wear Sleeve (Without Removing Timing Gear Cover)

Check Crankshaft End Play

Inspect Flywheel

Remove Flywheel

Replace Flywheel Ring Gear

Install Flywheel

Crankshaft Rear Oil Seal and Wear Sleeve Handling Precautions

Remove Unitized (Non-Separable) Crankshaft Rear Oil Seal and Wear Sleeve

Install Crankshaft Rear Oil Seal and Wear Sleeve

Remove Flywheel Housing

Remove Crankshaft Main Bearings

Check Main Bearing Oil Clearance

Remove and Install Crankshaft Gear (Crankshaft Installed In Engine)

Remove Crankshaft

Inspect Crankshaft

Measure Assembled Main Bearing ID and OD of Crankshaft Main Journal and Rod Journal

Measure Main Thrust Journal Width and Thrust Bearing Width

Crankshaft Grinding Guidelines

Measure Assembled ID of Main Bearing Caps

Remove, Inspect, and Install Piston Cooling Orifices

Install Main and Thrust Bearing Inserts in Block

Install Crankshaft

Install Flywheel Housing

Complete Final Assembly

Camshaft and Timing Gear Train

Special or Essential Tools

Service Equipment and Tools

Other Material

Camshaft and Timing Gear Train Specifications

Measure Valve Lift

Remove Timing Gear Cover

Remove and Install Camshaft Bushing With Front Plate Installed

Measure Camshaft End Play

Measure Idler Gear End Play

Measure Timing Gear Backlash

Remove Camshaft

Visually Inspect Camshaft

Measure Camshaft Thrust Plate Clearance

Inspect and Measure Camshaft Bushing ID and Journal OD

Measure Camshaft Lobe Height

Remove and Install Camshaft Gear

Inspect Camshaft Followers

Remove Cylinder Block Front Plate

Measure Idler Gear Bushing and Shaft

Remove and Install Idler Gear Bushing

Remove Lower and Upper Idler Shafts

Clean and Inspect Front Plate

Install Idler Shaft Spring Pins

Install Upper Idler Shaft in Front Plate

Install Lower Idler Shaft in Front Plate

Install Engine Front Plate

Install and Time Camshaft

Clean and Inspect Timing Gear Cover

Install Timing Gear Cover

Install Crankshaft Front Wear Sleeve and Oil Seal

Complete Final Assembly

Lubrication System

Special or Essential Tools

Service Equipment and Tools

Other Material

Lubrication System Specifications

Diagnosing Lubrication System Malfunctions

Remove, Inspect, and Install Oil Filter Base

Remove, Inspect, and Install Oil Cooler

Remove, Inspect, and Install Oil Bypass Valve

Remove and Install Oil Pressure Regulating Valve and Seat

Remove and Install Oil Fill Tube

Remove and Install Dipstick Tube With Oil Pan Installed

Replace Oil Pump Pick-Up Tube Assembly

Engine Oil Pump Assembly

Remove Engine Oil Pump

Inspect and Measure Clearances

Complete Oil Pump Disassembly

Assemble Engine Oil Pump

Install Engine Oil Pump

Install Oil Pan

Cooling System

Special or Essential Tools

Service Equipment and Tools

Other Material

Cooling System Specifications

Diagnosing Cooling System Malfunctions

Remove Water Manifold/Thermostat Cover and Thermostat

Test Thermostat

Install Water Manifold/Thermostat Cover and Thermostat

Remove Water Pump

Water Pump Assembly

Disassemble Water Pump

Inspect, Clean, and Measure Water Pump Parts

Assemble Water Pump

Install Water Pump

Remove and Install Automatic (Spring) Belt Tensioner

Checking Belt Tensioner Spring Tension and Belt Wear

Remove and Inspect Idler Pulley Assembly

Replace Bearing in Idler Pulley Assembly

Install Idler Pulley Assembly

Remove and Install Coolant Heater

Air Intake and Exhaust System

Other Material

Air Intake and Exhaust System Specifications

Extending Turbocharger Life

Remove Turbocharger

Turbocharger Failure Analysis

Turbocharger Seven-Step Inspection

Perform Axial Bearing End Play Test

Repair Turbocharger

Clean and Inspect Turbine and Compressor Housings

Adjust Turbocharger Wastegate Actuator

Prelube Turbocharger

Install Turbocharger

Cleaning PCV Orifice

Remove, Inspect, and Install Exhaust Manifold

Remove, Inspect, and Install Intake Manifold

Fuel Supply System

Specifications

Fuel Pressure Leak-Off Procedure

Leak Check Procedure

Remove and Install Natural Gas Regulator

Repair Natural Gas Regulator

Remove and Install Fuel Metering Valve

Repair Fuel Metering Valve

Remove and Install Fuel Mixer

Starting and Charging System

Special or Essential Tools

Specifications

Remove and Install Starter

Bench Test Starting Motor

Make Solenoid Return Test

Make No Load Test

Diagnose No Load Test

Remove and Install Alternator

Charging System Failure

Alternator Troubleshooting

Alternator Output Test

Diode Trio Test

Full Field Test

Electronic Engine Controls

Special or Essential Tools

Service Equipment and Tools

Other Material

Specifications

Remove and Install Spark Plugs

Removal of Seized Spark Plugs (Tool JDG1193 Not Available or Spark Plug Ceramic Stem Has Broken Off)

Remove and Install Ignition Coils

Remove and Install Ignition Control Unit (ICU)

Remove and Install Cam Sensor

Remove and Install Crank Sensor

Remove and Install Engine Coolant Temperature (ECT) Sensor

Remove and Install Foot Pedal Position Sensor

Remove and Install Manifold Absolute Pressure (MAP) Sensor

Remove and Install Manifold Air Temperature (MAT) Sensor

Remove and Install Natural Gas Tank Temperature (NGTT) Sensor

Remove and Install Preturbine Pressure (PTP) Sensor

Remove and Install Exhaust Back Pressure (EBP) Sensor

Remove and Install Electronic Throttle and Throttle Position Sensor

Remove and Install Universal Exhaust Gas Oxygen (UEGO) Sensor

Remove and Install Oil Pressure Switch

Remove and Install Turbocharger Wastegate Control Valve

Natural Gas Engine Wiring Harness

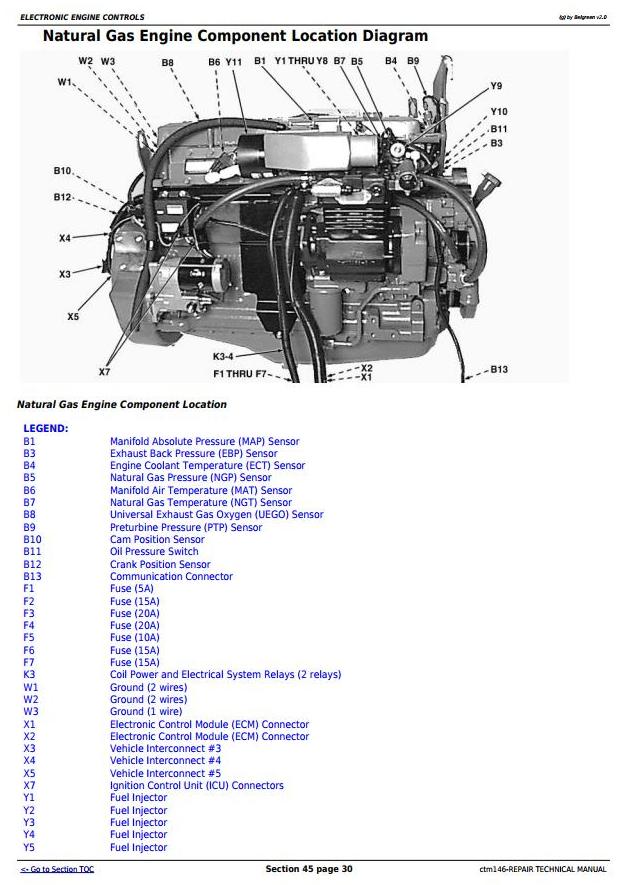

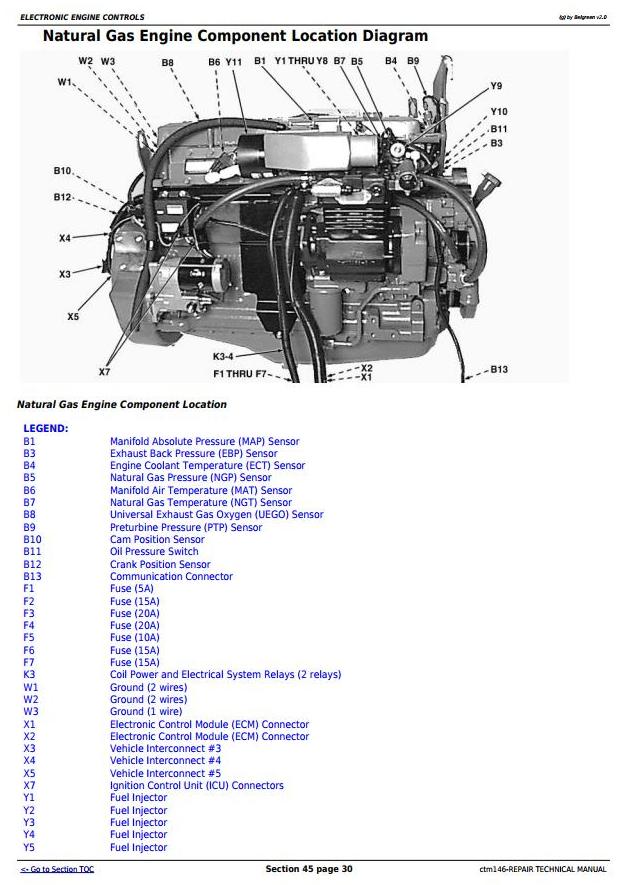

Natural Gas Engine Component Location Diagram

Connectors

Using High-Pressure Washer

Replace WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Connector

Install WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Contact

Remove Connector Body from Blade Terminals

Replace (Pull Type) METRI-PACK METRI-PACK is a trademark of Packard Electric. Connectors

Replace (Push Type) METRI-PACK METRI-PACK is a trademark of Packard Electric. Connectors

Use Electrical Insulating Compound

Replace DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Connectors

Install DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Contact

Miscellaneous Accessories

Other Material

Miscellaneous Accessories Specifications

Remove Air Compressor

Inspecting Air Compressor

Remove Idler Housing

Install Idler Housing

Install Air Compressor

Dealer Fabricated Tools

Dealer Fabricated Tools

DFRG3 Cylinder Liner Holding Fixture

Format: PDF

Language: English

Type of Document: Component Technical Manual

Type of Machine: PowerTech

Number of Pages: 485 pages

Part Number: CTM146

Model: John Deere 6.8L 6068 Repair Component Technical Manual

John Deere 6068CNG

Content:

Foreword

About This Manual

Safety

Handle Fluids Safely-Avoid Fires

Handle Natural Gas Safely

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Avoid High-Pressure Fluids

Wear Protective Clothing

Service Machines Safely

Work in Ventilated Area

Work in Clean Area

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Illuminate Work Area Safely

Use Proper Lifting Equipment

Practice Safe Maintenance

Use Proper Tools

Dispose of Waste Properly

Handle Compressed Natural Gas (CNG) Safely

Service Compressed Natural Gas (CNG) Systems Safely

Protect Against High Pressure

Protect Against Extremely Cold CNG Leakage

Live With Safety

General Information

Unified Inch Bolt and Cap Screw Torque Values

Metric Bolt and Cap Screw Torque Values

Engine Model Designation

Engine Serial Number Plate Information

Fuels, Lubricants, and Coolant

Natural Gas Recommendations

Natural Gas Engine Oil

Engine Break-In Oil

Alternative and Synthetic Lubricants

Mixing of Lubricants

OILSCANOILSCAN is a trademark of Deere & Company. and CoolScanCoolScan is a trademark of Deere & Company.

Grease

Recommended Engine Coolant

Engine Coolant Specifications

Testing Diesel Engine Coolant

Replenishing Supplemental Coolant Additives (SCA’s) Between Coolant Changes

Operating in Warm Temperature Climates

Flush and Service Cooling System

Disposing of Coolant

Engine Mounting

Engine Repair Stand

Safety Precautions

Install Adapters on Engine Repair Stand

Engine Lifting Procedure

Clean Engine

Disconnect Turbocharger Oil Inlet Line

Mount Engine on Repair Stand

Engine Mounted on Repair Stand

Engine Rebuild Guide

Engine Disassembly Sequence

Sealant Application Guidelines

Engine Assembly Sequence

Cylinder Head and Valves

Special or Essential Tools

Service Equipment and Tools

Other Material

Cylinder Head and Valves Specifications

Check and Adjust Valve Clearance

Measure Valve Lift

Remove Cylinder Head

Disassemble and Inspect Rocker Arm Shaft Assembly

Assemble Rocker Arm Assembly

Inspect, Measure, and Assemble Camshaft Followers

Measure Valve Recess in Cylinder Head

Preliminary Cylinder Head and Valve Checks

Remove Valve Assembly

Inspect and Measure Valve Springs

Inspect Valve Rotators

Clean Valves

Inspect and Measure Valves

Grind Valves

Inspect and Clean Cylinder Head

Check Cylinder Head Flatness

Measure Cylinder Head Thickness

Clean Valve Guides

Measure Valve Guides

Knurl Valve Guides

Clean and Inspect Valve Seats

Grind Valve Seats

Remove Valve Seat Inserts

Measure Valve Seat Bore in Cylinder Head

Install Valve Seat Inserts

Install Valves

Inspect and Clean Exhaust Manifold

Clean and Inspect Top Deck of Cylinder Block

Measure Cylinder Liner Standout (Height Above Block)

Install Cylinder Head and Cap Screws

Torque-Turn Method for Proper Torque

Install Rocker Arm Assembly

Inspect and Clean Ventilator Outlet Hose

Install Rocker Arm Cover

Complete Final Assembly

Perform Engine Break-In

Cylinder Block, Liners, Pistons, and Rods

Special or Essential Tools

Service Equipment and Tools

Other Material

Cylinder Block, Liners, Pistons, and Rods Specifications

Connecting Rods-General Information

Remove Pistons and Connecting Rods

Remove Cylinder Liners

Complete Disassembly of Cylinder Block (If Required)

Preliminary Liner, Piston and Rod Checks

Disassemble Piston and Rod Assembly

Clean Pistons

Visually Inspect Pistons

Clean Cylinder Liners

Visually Inspect Cylinder Liners

Check Piston Ring Groove Wear

Measure Piston Pin Bore

Measure Piston Skirt

Determine Piston-to-Liner Clearance

Deglaze Cylinder Liners

Replace Piston and Liner Sets

Inspect and Measure Connecting Rod Bearings

Inspect Rod and Cap

Inspect Piston Pins and Bushings

Remove Piston Pin Bushing

Clean and Inspect Connecting Rod Pin Bore

Install Piston Pin Bushing in Connecting Rod

Measure Rod Center-to-Center Bores

Inspect and Clean Cylinder Block

Clean Cylinder Liner O-Ring Bore

Measure Cylinder Block Main Bearing Bore

Measure Camshaft Follower Machined Bore in Block

Measure Camshaft Bushing Bores in Block

Measure Liner Flange Counterbore Depth in Block

Measure Liner Flange Thickness

Measure Cylinder Block Top Deck Flatness

Remove, Inspect, and Install Piston Cooling Orifices

Measure Cylinder Liner Standout (Height Above Block)

Install Packing on Cylinder Liner and O-Rings in Block

Install Cylinder Liner in Block

Assemble Connecting Rods onto Piston

Install Piston Rings

Connecting Rods-General Information

Install Piston and Rod Assembly

Torque-Turn Connecting Rod Cap Screws

Check Engine Rotation for Excessive Tightness

Measure Piston Protrusion

Complete Final Assembly

Crankshaft, Main Bearings, and Flywheel

Special or Essential Tools

Service Equipment and Tools

Other Material

Crankshaft, Main Bearings, and Flywheel Specifications

Crankshaft Grinding Specifications

Crankshaft and Main Bearing Failure Analysis

Inspect Vibration Damper

Remove Pulley or Vibration Damper and Pulley

Install Pulley or Vibration Damper Pulley

Checking Vibration Damper or Pulley

Replace Front Crankshaft Oil Seal and Wear Sleeve (Without Removing Timing Gear Cover)

Check Crankshaft End Play

Inspect Flywheel

Remove Flywheel

Replace Flywheel Ring Gear

Install Flywheel

Crankshaft Rear Oil Seal and Wear Sleeve Handling Precautions

Remove Unitized (Non-Separable) Crankshaft Rear Oil Seal and Wear Sleeve

Install Crankshaft Rear Oil Seal and Wear Sleeve

Remove Flywheel Housing

Remove Crankshaft Main Bearings

Check Main Bearing Oil Clearance

Remove and Install Crankshaft Gear (Crankshaft Installed In Engine)

Remove Crankshaft

Inspect Crankshaft

Measure Assembled Main Bearing ID and OD of Crankshaft Main Journal and Rod Journal

Measure Main Thrust Journal Width and Thrust Bearing Width

Crankshaft Grinding Guidelines

Measure Assembled ID of Main Bearing Caps

Remove, Inspect, and Install Piston Cooling Orifices

Install Main and Thrust Bearing Inserts in Block

Install Crankshaft

Install Flywheel Housing

Complete Final Assembly

Camshaft and Timing Gear Train

Special or Essential Tools

Service Equipment and Tools

Other Material

Camshaft and Timing Gear Train Specifications

Measure Valve Lift

Remove Timing Gear Cover

Remove and Install Camshaft Bushing With Front Plate Installed

Measure Camshaft End Play

Measure Idler Gear End Play

Measure Timing Gear Backlash

Remove Camshaft

Visually Inspect Camshaft

Measure Camshaft Thrust Plate Clearance

Inspect and Measure Camshaft Bushing ID and Journal OD

Measure Camshaft Lobe Height

Remove and Install Camshaft Gear

Inspect Camshaft Followers

Remove Cylinder Block Front Plate

Measure Idler Gear Bushing and Shaft

Remove and Install Idler Gear Bushing

Remove Lower and Upper Idler Shafts

Clean and Inspect Front Plate

Install Idler Shaft Spring Pins

Install Upper Idler Shaft in Front Plate

Install Lower Idler Shaft in Front Plate

Install Engine Front Plate

Install and Time Camshaft

Clean and Inspect Timing Gear Cover

Install Timing Gear Cover

Install Crankshaft Front Wear Sleeve and Oil Seal

Complete Final Assembly

Lubrication System

Special or Essential Tools

Service Equipment and Tools

Other Material

Lubrication System Specifications

Diagnosing Lubrication System Malfunctions

Remove, Inspect, and Install Oil Filter Base

Remove, Inspect, and Install Oil Cooler

Remove, Inspect, and Install Oil Bypass Valve

Remove and Install Oil Pressure Regulating Valve and Seat

Remove and Install Oil Fill Tube

Remove and Install Dipstick Tube With Oil Pan Installed

Replace Oil Pump Pick-Up Tube Assembly

Engine Oil Pump Assembly

Remove Engine Oil Pump

Inspect and Measure Clearances

Complete Oil Pump Disassembly

Assemble Engine Oil Pump

Install Engine Oil Pump

Install Oil Pan

Cooling System

Special or Essential Tools

Service Equipment and Tools

Other Material

Cooling System Specifications

Diagnosing Cooling System Malfunctions

Remove Water Manifold/Thermostat Cover and Thermostat

Test Thermostat

Install Water Manifold/Thermostat Cover and Thermostat

Remove Water Pump

Water Pump Assembly

Disassemble Water Pump

Inspect, Clean, and Measure Water Pump Parts

Assemble Water Pump

Install Water Pump

Remove and Install Automatic (Spring) Belt Tensioner

Checking Belt Tensioner Spring Tension and Belt Wear

Remove and Inspect Idler Pulley Assembly

Replace Bearing in Idler Pulley Assembly

Install Idler Pulley Assembly

Remove and Install Coolant Heater

Air Intake and Exhaust System

Other Material

Air Intake and Exhaust System Specifications

Extending Turbocharger Life

Remove Turbocharger

Turbocharger Failure Analysis

Turbocharger Seven-Step Inspection

Perform Axial Bearing End Play Test

Repair Turbocharger

Clean and Inspect Turbine and Compressor Housings

Adjust Turbocharger Wastegate Actuator

Prelube Turbocharger

Install Turbocharger

Cleaning PCV Orifice

Remove, Inspect, and Install Exhaust Manifold

Remove, Inspect, and Install Intake Manifold

Fuel Supply System

Specifications

Fuel Pressure Leak-Off Procedure

Leak Check Procedure

Remove and Install Natural Gas Regulator

Repair Natural Gas Regulator

Remove and Install Fuel Metering Valve

Repair Fuel Metering Valve

Remove and Install Fuel Mixer

Starting and Charging System

Special or Essential Tools

Specifications

Remove and Install Starter

Bench Test Starting Motor

Make Solenoid Return Test

Make No Load Test

Diagnose No Load Test

Remove and Install Alternator

Charging System Failure

Alternator Troubleshooting

Alternator Output Test

Diode Trio Test

Full Field Test

Electronic Engine Controls

Special or Essential Tools

Service Equipment and Tools

Other Material

Specifications

Remove and Install Spark Plugs

Removal of Seized Spark Plugs (Tool JDG1193 Not Available or Spark Plug Ceramic Stem Has Broken Off)

Remove and Install Ignition Coils

Remove and Install Ignition Control Unit (ICU)

Remove and Install Cam Sensor

Remove and Install Crank Sensor

Remove and Install Engine Coolant Temperature (ECT) Sensor

Remove and Install Foot Pedal Position Sensor

Remove and Install Manifold Absolute Pressure (MAP) Sensor

Remove and Install Manifold Air Temperature (MAT) Sensor

Remove and Install Natural Gas Tank Temperature (NGTT) Sensor

Remove and Install Preturbine Pressure (PTP) Sensor

Remove and Install Exhaust Back Pressure (EBP) Sensor

Remove and Install Electronic Throttle and Throttle Position Sensor

Remove and Install Universal Exhaust Gas Oxygen (UEGO) Sensor

Remove and Install Oil Pressure Switch

Remove and Install Turbocharger Wastegate Control Valve

Natural Gas Engine Wiring Harness

Natural Gas Engine Component Location Diagram

Connectors

Using High-Pressure Washer

Replace WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Connector

Install WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Contact

Remove Connector Body from Blade Terminals

Replace (Pull Type) METRI-PACK METRI-PACK is a trademark of Packard Electric. Connectors

Replace (Push Type) METRI-PACK METRI-PACK is a trademark of Packard Electric. Connectors

Use Electrical Insulating Compound

Replace DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Connectors

Install DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Contact

Miscellaneous Accessories

Other Material

Miscellaneous Accessories Specifications

Remove Air Compressor

Inspecting Air Compressor

Remove Idler Housing

Install Idler Housing

Install Air Compressor

Dealer Fabricated Tools

Dealer Fabricated Tools

DFRG3 Cylinder Liner Holding Fixture

More the random threads same category:

- JOHN DEERE JD-410 Technical Manual

- Funk Power DF Series 150 & 250 Transmission Service Manual

- John Deere Service ADVISOR 4.0 CF+JDIN+History Data (11.2013)

- John Deere Parts Manager Pro 6.5.5 (CF) Construction & Foresty [03.2016]

- John Deere Service Advisor 4.1.011 + 4 dvd data RU (01.2013)

- John Deere 750C,850C Crawler Dozer Technical Manual

- John Deere Service Advisor 4.01.11

- John Deere 750J,850J Crawler Dozer Parts Catalog

- John Deere 6020 Series Repair Manuals (6020 to 6920S)

- John Deere Service Advisor 4.1.007 Torrent 28.11.2013

- Jonh Dree 690E LC Excavator Techical Manual

- John Deere 700J Crawler Dozer Parts Catalog

- John Deere 850J Crawler Dozer Tier 3 Parts Catalog

- John Deere LTR155, LTR166 and LTR180 Lawn Tractors Technical manual

- JOHN DEERE CODE DTC LIST