- Gallons

- 288,708

[Linkbelt] Linkbelt Excavator 250X4 MH SL Operator Manual 250X4-MH-OM-LXG-02

- Download this document, you need 1605 Gallons

Linkbelt Excavator 250X4 MH SL Operator Manual 250X4-MH-OM-LXG-02

Size: 53.6 MB

Format: PDF

Language: English

Brand: Link-Belt

Type of Machine: Excavator

Type of Document: Operator Manual

Model: Link-Belt 250X4-MH Material Handler, Link-Belt 250X4-SL Scrap Loader

Number of Pages: 281 Pages

Contents:

CHAPTER 1 – TO THE OWNER

LINK-BELT TECHNICAL MANUALS

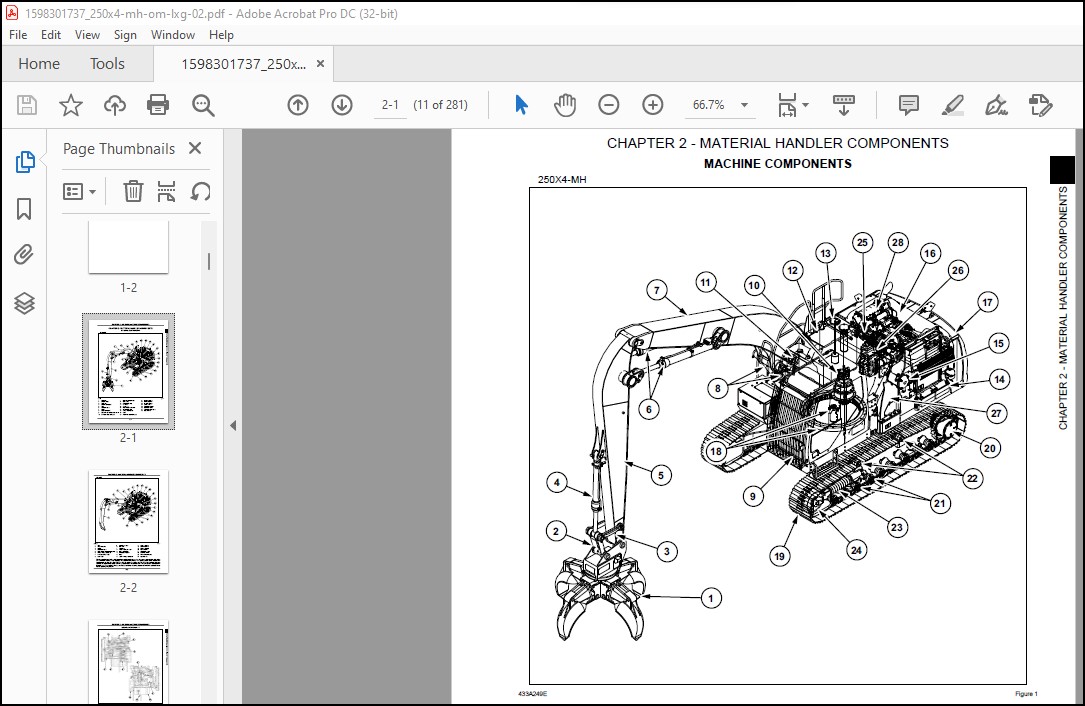

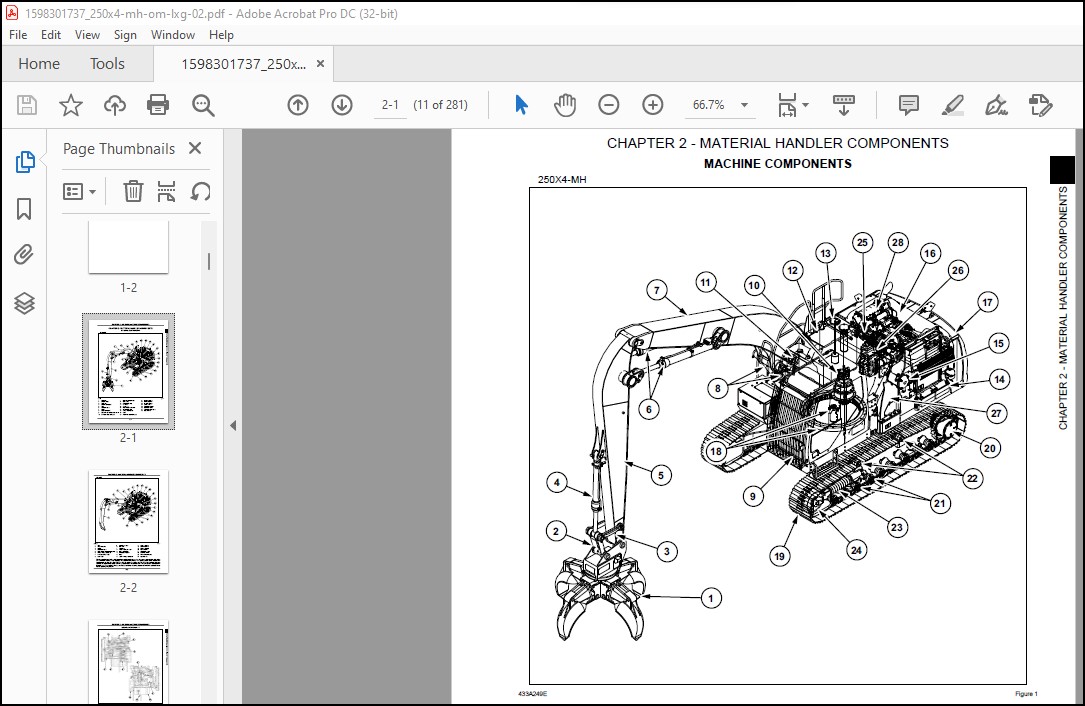

CHAPTER 2 – MATERIAL HANDLER COMPONENTS

MACHINE COMPONENTS

ENGINE COMPONENTS

IDENTIFICATION NUMBERS

CHAPTER 3 – SAFETY, DECALS, AND HAND SIGNALS

SAFETY RULES

SAFETY AREA

UTILITY SAFETY

OPERATOR PRECAUTIONS

DECALS

HAND SIGNALS

CHAPTER 4 – INSTRUMENTS AND CONTROLS

CAB

STEPS AND ACCESS HANDLES

POSITION OF THE CAB CONTROLS AND ACCESSORIES

OPERATOR’S SEAT

SEAT CONTROLS

RIGHT HAND CONTROL ARM

LEFT HAND CONTROL ARM

FRONT RIGHT CONSOLE

HAND CONTROL LEVERS AND PEDALS(250X4-MH)

HAND CONTROL LEVERS AND PEDALS(250X4-SL)

TRAVEL CONTROL

SINGLE PEDAL TRAVEL

GATE LOCK

CAB LIGHT

COAT HANGER HOOK

CAB DOOR WINDOWS

CUP HOLDER

STORAGE TRAY

STORAGE COMPARTMENT

FUSE BOX

RADIO

WINDSHIELD

LOWER FRONT WINDOW

CAB FRONT GUARD

AIR VENTS

REAR WINDOW

REAR VIEW MIRRORS

MIRROR INSTALLATION AND ADJUSTMENT

REAR VIEW CAMERA

UNDER VIEW CAMERA (OPTIONAL)

FUEL TANK

ENGINE HOOD

STORAGE BOX

WINDSHIELD WASHER RESERVOIR

SIDE DOOR

TOWING POINT

CAB PROTECTION (FOPS: Option)

CHAPTER 5 – OPERATING INSTRUCTIONS

BEFORE OPERATING THE MACHINE

OPERATING THE MACHINE

RUN-IN PERIOD

ANTI-INTERFERENCE SYSTEM

EMERGENCY LOWERING SYSTEM

STARTING THE UNIT

STARTING THE ENGINE

BRINGING THE MACHINE UP TO OPERATING TEMPERATURE

ENGINE OPERATION

STOPPING THE ENGINE

SCR SYSTEM

SCR RE-GEN (SCR regeneration)

OPERATING THE MACHINE IN COLD WEATHER

OPERATING THE MACHINE IN HOT WEATHER

BASIC OPERATION

SWING LOCK

MACHINE TRAVEL

SELECTION OF TRAVEL SPEED

PARKING THE MACHINE

OPERATING THE MACHINE ON SLOPING GROUND

TOWING THE MACHINE

LOAD HANDLING

LOWERING THE ATTACHMENT IN THE EVENT OF A MACHINE FAILURE

OPERATION OF ELEVATOR CAB

WORKING WITH THE MAGNET

OPERATION

ENGINE SPEED IN THE MAGNET MODE

AUXILIARY HYDRAULIC CIRCUITS

CHAPTER 6 – SERVICING INTERVALS

SERVICING INTERVALS

HOURMETER

DAILY INSPECTIONS

CHAPTER 7 – LUBRICATION, FILTERS, AND FLUIDS

FLUIDS AND LUBRICANTS

SAMPLING PROCEDURE

LUBRICATION CHART

LUBRICATION POINTS

FLUID LEVELS

ENGINE

COOLING SYSTEM

FUEL SYSTEM

DEF SYSTEM

RELEASING PRESSURE IN THE HYDRAULIC SYSTEM

HYDRAULIC SYSTEM

BLEEDING AIR FROM THE HYDRAULIC COMPONENTS

AIR FILTER

SWING REDUCTION GEAR

TRAVEL REDUCTION GEARS

CHAPTER 8 – MAINTENANCE AND ADJUSTMENTS

TRACKS

TRACK ROLLERS AND IDLER WHEELS

RADIATOR AND OIL COOLER

FAN AND ALTERNATOR BELT

INSPECTING AND CLEANING THE MACHINE

PLASTIC AND RESIN PARTS

CHECKING FOR CYLINDER LEAKAGE

FIRE EXTINGUISHER (NOT SUPPLIED)

PROTECTION OF ELECTRIC / ELECTRONICS SYSTEM DURING CHARGING OR WELDING

AIR CONDITIONING

INSPECTION OF GAS SPRING

HARDWARE TORQUE INSPECTION

ENGINE TROUBLESHOOTING

CHAPTER 9 – ELECTRICAL SYSTEMS

FUSES

BATTERY DISCONNECT SWITCH

BATTERY

CONNECTING ONE OR TWO BOOSTER BATTERIES

ALTERNATOR

STARTER MOTOR

REPLACING A BULB

MAGNET SYSTEM MAINTENANCE SPECIFICATION

CHAPTER 10 – TRANSPORTATION & STORAGE INSTRUCTIONS

TRANSPORTING THE MACHINE

LIFTING THE MACHINE

DISASSEMBLY BEFORE TRANSPORT

MACHINE STORAGE

CHAPTER 11 – SPECIFICATIONS

ENGINE

ELECTRICAL SYSTEMS

HYDRAULIC SYSTEM

WEIGHTS

UNDERCARRIAGE

CAPACITY OF SYSTEMS AND COMPONENTS

ATTACHMENT

EXCAVATOR OVERALL DIMENSIONS

WORKING RANGE

LIFTING CAPACITIES – ISO RATINGS

RemoteCARE

DECLARATION FCC & CE

DOCUMENT

CHAPTER 12 INDEX

Size: 53.6 MB

Format: PDF

Language: English

Brand: Link-Belt

Type of Machine: Excavator

Type of Document: Operator Manual

Model: Link-Belt 250X4-MH Material Handler, Link-Belt 250X4-SL Scrap Loader

Number of Pages: 281 Pages

Contents:

CHAPTER 1 – TO THE OWNER

LINK-BELT TECHNICAL MANUALS

CHAPTER 2 – MATERIAL HANDLER COMPONENTS

MACHINE COMPONENTS

ENGINE COMPONENTS

IDENTIFICATION NUMBERS

CHAPTER 3 – SAFETY, DECALS, AND HAND SIGNALS

SAFETY RULES

SAFETY AREA

UTILITY SAFETY

OPERATOR PRECAUTIONS

DECALS

HAND SIGNALS

CHAPTER 4 – INSTRUMENTS AND CONTROLS

CAB

STEPS AND ACCESS HANDLES

POSITION OF THE CAB CONTROLS AND ACCESSORIES

OPERATOR’S SEAT

SEAT CONTROLS

RIGHT HAND CONTROL ARM

LEFT HAND CONTROL ARM

FRONT RIGHT CONSOLE

HAND CONTROL LEVERS AND PEDALS(250X4-MH)

HAND CONTROL LEVERS AND PEDALS(250X4-SL)

TRAVEL CONTROL

SINGLE PEDAL TRAVEL

GATE LOCK

CAB LIGHT

COAT HANGER HOOK

CAB DOOR WINDOWS

CUP HOLDER

STORAGE TRAY

STORAGE COMPARTMENT

FUSE BOX

RADIO

WINDSHIELD

LOWER FRONT WINDOW

CAB FRONT GUARD

AIR VENTS

REAR WINDOW

REAR VIEW MIRRORS

MIRROR INSTALLATION AND ADJUSTMENT

REAR VIEW CAMERA

UNDER VIEW CAMERA (OPTIONAL)

FUEL TANK

ENGINE HOOD

STORAGE BOX

WINDSHIELD WASHER RESERVOIR

SIDE DOOR

TOWING POINT

CAB PROTECTION (FOPS: Option)

CHAPTER 5 – OPERATING INSTRUCTIONS

BEFORE OPERATING THE MACHINE

OPERATING THE MACHINE

RUN-IN PERIOD

ANTI-INTERFERENCE SYSTEM

EMERGENCY LOWERING SYSTEM

STARTING THE UNIT

STARTING THE ENGINE

BRINGING THE MACHINE UP TO OPERATING TEMPERATURE

ENGINE OPERATION

STOPPING THE ENGINE

SCR SYSTEM

SCR RE-GEN (SCR regeneration)

OPERATING THE MACHINE IN COLD WEATHER

OPERATING THE MACHINE IN HOT WEATHER

BASIC OPERATION

SWING LOCK

MACHINE TRAVEL

SELECTION OF TRAVEL SPEED

PARKING THE MACHINE

OPERATING THE MACHINE ON SLOPING GROUND

TOWING THE MACHINE

LOAD HANDLING

LOWERING THE ATTACHMENT IN THE EVENT OF A MACHINE FAILURE

OPERATION OF ELEVATOR CAB

WORKING WITH THE MAGNET

OPERATION

ENGINE SPEED IN THE MAGNET MODE

AUXILIARY HYDRAULIC CIRCUITS

CHAPTER 6 – SERVICING INTERVALS

SERVICING INTERVALS

HOURMETER

DAILY INSPECTIONS

CHAPTER 7 – LUBRICATION, FILTERS, AND FLUIDS

FLUIDS AND LUBRICANTS

SAMPLING PROCEDURE

LUBRICATION CHART

LUBRICATION POINTS

FLUID LEVELS

ENGINE

COOLING SYSTEM

FUEL SYSTEM

DEF SYSTEM

RELEASING PRESSURE IN THE HYDRAULIC SYSTEM

HYDRAULIC SYSTEM

BLEEDING AIR FROM THE HYDRAULIC COMPONENTS

AIR FILTER

SWING REDUCTION GEAR

TRAVEL REDUCTION GEARS

CHAPTER 8 – MAINTENANCE AND ADJUSTMENTS

TRACKS

TRACK ROLLERS AND IDLER WHEELS

RADIATOR AND OIL COOLER

FAN AND ALTERNATOR BELT

INSPECTING AND CLEANING THE MACHINE

PLASTIC AND RESIN PARTS

CHECKING FOR CYLINDER LEAKAGE

FIRE EXTINGUISHER (NOT SUPPLIED)

PROTECTION OF ELECTRIC / ELECTRONICS SYSTEM DURING CHARGING OR WELDING

AIR CONDITIONING

INSPECTION OF GAS SPRING

HARDWARE TORQUE INSPECTION

ENGINE TROUBLESHOOTING

CHAPTER 9 – ELECTRICAL SYSTEMS

FUSES

BATTERY DISCONNECT SWITCH

BATTERY

CONNECTING ONE OR TWO BOOSTER BATTERIES

ALTERNATOR

STARTER MOTOR

REPLACING A BULB

MAGNET SYSTEM MAINTENANCE SPECIFICATION

CHAPTER 10 – TRANSPORTATION & STORAGE INSTRUCTIONS

TRANSPORTING THE MACHINE

LIFTING THE MACHINE

DISASSEMBLY BEFORE TRANSPORT

MACHINE STORAGE

CHAPTER 11 – SPECIFICATIONS

ENGINE

ELECTRICAL SYSTEMS

HYDRAULIC SYSTEM

WEIGHTS

UNDERCARRIAGE

CAPACITY OF SYSTEMS AND COMPONENTS

ATTACHMENT

EXCAVATOR OVERALL DIMENSIONS

WORKING RANGE

LIFTING CAPACITIES – ISO RATINGS

RemoteCARE

DECLARATION FCC & CE

DOCUMENT

CHAPTER 12 INDEX

More the random threads same category:

- Linkbelt LS108C Parts, Operation Maintenance and Load Chart Manuals

- Linkbelt Greer BBTM-508/BB-509 ANTI TWO-BLOCK ALARM SYSTEM – HYDRAULIC CRANE SYSTEM LAYOUT

- Link Belt 350X3 Excavator Schematic Service Manual

- Linkbet LS 118 Operator's Manual

- Link Belt 145X3 Hydraulic Excavators Operator's Manual

- Link Belt 3400 Quantum Excavator Schematic Shop Manual

- Link Belt HTC86100 Operator's Manual

- Link Belt RTC80130 Parts Manual

- Linkbelt RTC-8065 II Operator's Manual (Spanish)

- Link Belt 2800 Quantum Excavator Shop Manual

- Link Belt RTC-80130 II Operator's Manual

- Linkbelt LS 98 Operator's Manual

- Link Belt 210X2-EX Excavators Parts Manual

- MicroGuard 404 Trouble Shooting Manual

- Linkbelt LS-278 Rated Capacity Limiter Operators Manual