Hyster Forklift Claas 3 A3D9 (P2.0S-P2.5S-P3.0S Europe) Service Manual 03.2022

- Download this document, you need 2725 Gallons

Hyster Forklift Claas 3 A3D9 (P2.0S-P2.5S-P3.0S Europe) Service Manual 03.2022

Size: 56.6 MB

Format: PDF

Language: English

Brand: Hyster

Model: Hyster A3D9 P2.0S, P2.5S, P3.0S EU Service Manual 03.2022

Type of machine: Forklift Truck

Type of document: Service Manual

Content:

Important

General safety rules

Torque settings for screws nuts and fittings

Correct method for applying female fittings

Instruction for installing flexible hoses and fittings

Truck presentation

Views of the truck

Truck and load identification data

General specification

Traction wheel

Removal of the traction wheel

Torsion bar castor wheel assembly

Torsion bar castor wheel group disassembly

Replacement of the castor wheel torsion bar springs

Replacing the castor wheel

Replacing the castor wheel group

Load wheels

Replacing the tandem load wheel

Replacing the tandem load wheel assembly

Fixed linkage

Adjustable linkage

Removal of the linkage assembly

Key to tiller components

Tiller spring replacement

Adjustable steering spring replacement

Tiller removal

Replacement of the potentiometer and tiller base bearings

Replacement of the potentiometer and tiller base bearings of the adjustable steering

Key to scooter components

Scooter head removal

Scooter spring replacement

Replacement of the scooter control sensor and base bearings

Side gate replacement

Side gates microswitch replacement

Removal of the platform gas spring

Replacement of the platform touchless sensor

Removal of the platform

Replacement of the platform sensor

Traction motor

Motor dismantling

Steering motor

Steering motor dismantling

Forks chassis removal

Removal of the reduction unit

Disassembly of the reduction unit

Braking System

Removal of the electromagnetic brake

Before Installation

Truck assembly

Topping up the oil reservoir

Installation of the battery with vertical extraction

Installation of the battery with lateral extraction

Connection of cables to battery

List and description of the settings and adjustments to be carried out

Description of controller connectors

Device properties

Monitor menu

Troubleshooting

Warnings

Diagnosis system for F4-A Controller

Diagnosis system for Integrated Steering System

Electrical component measurements

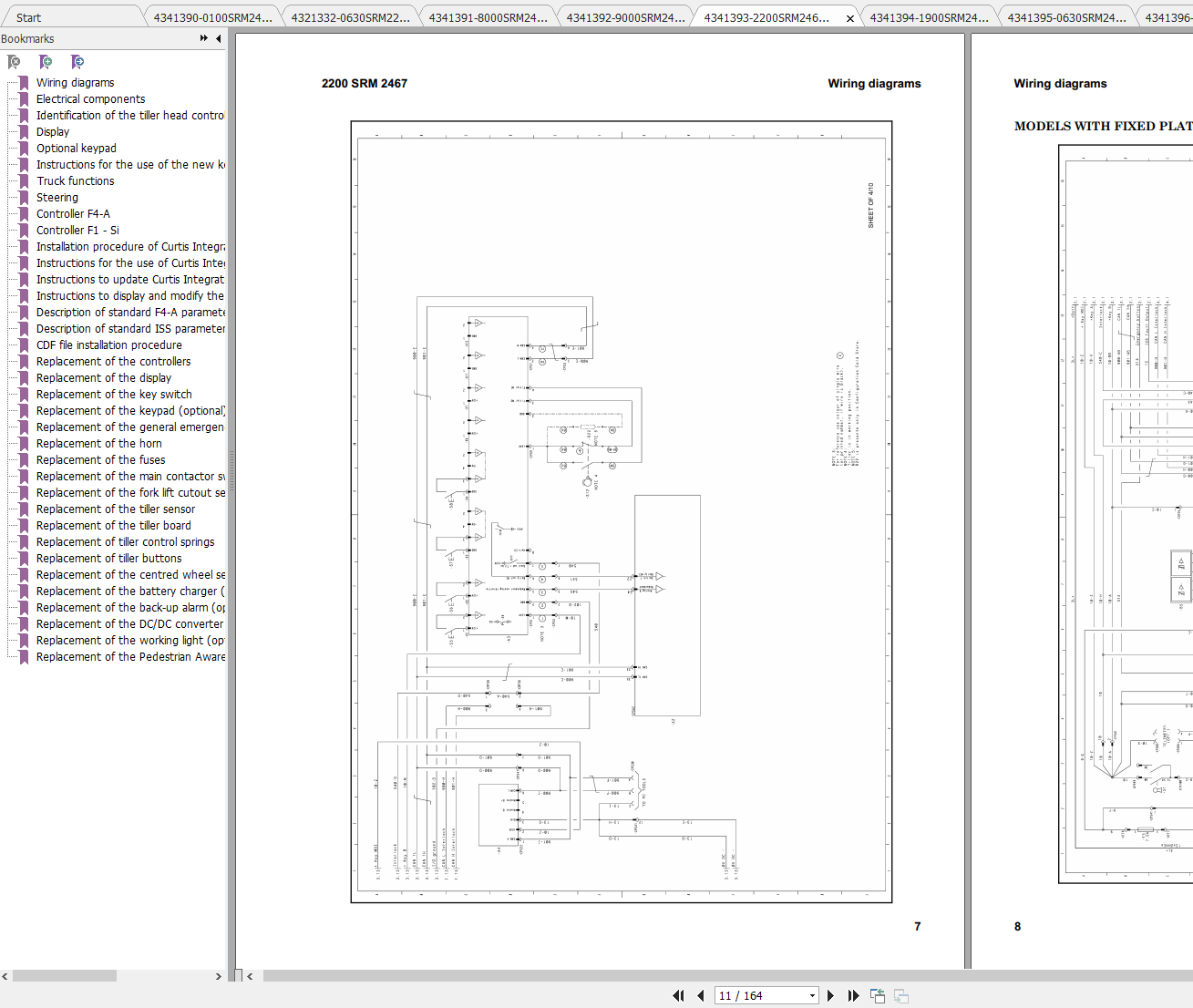

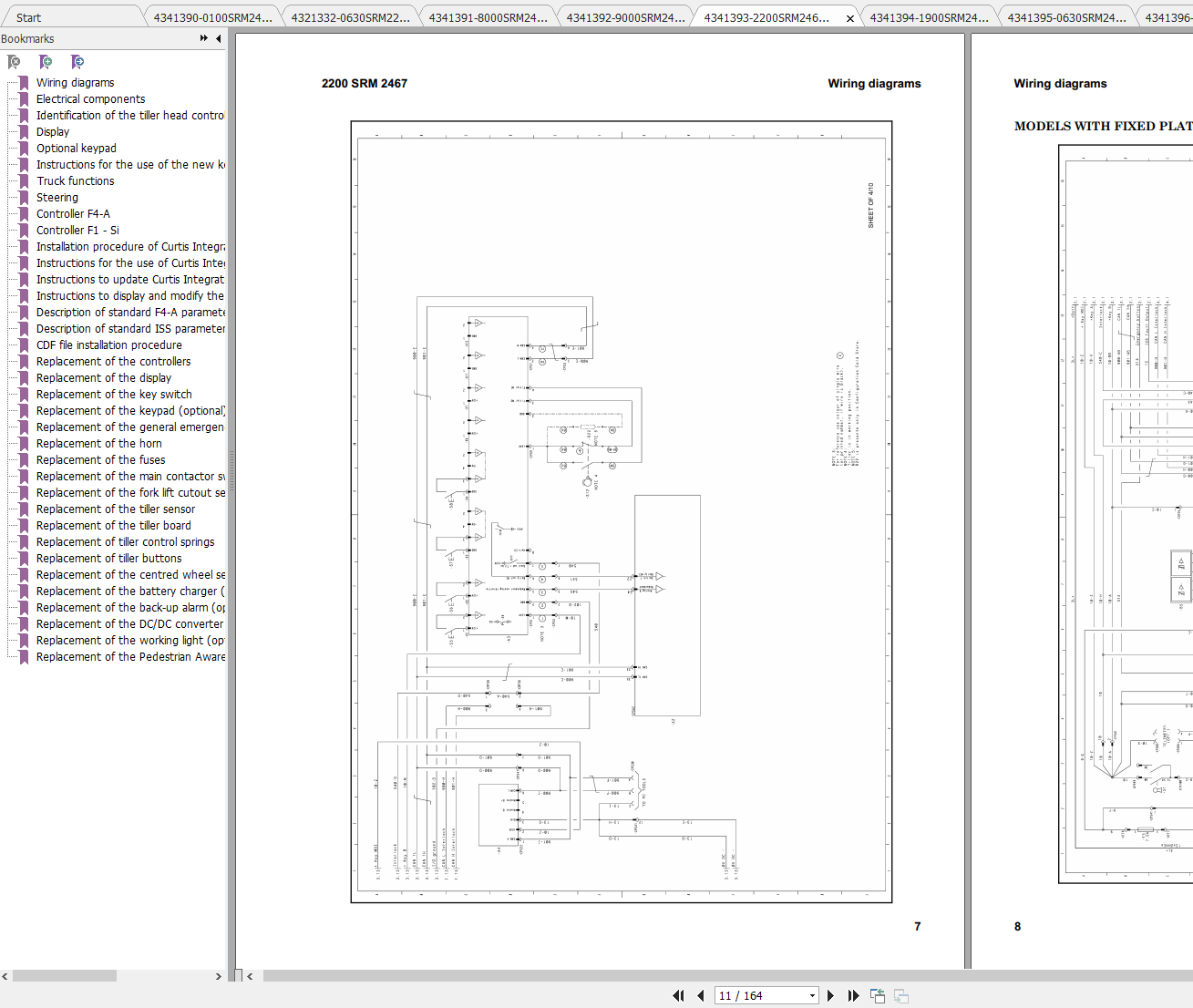

Wiring diagrams

Electrical components

Identification of the tiller head controls and of the operator panel instruments

Display

Optional keypad

Instructions for the use of the new keypad application

Truck functions

Steering

Controller F4-A

Controller F1 - Si

Installation procedure of Curtis Integrated Toolkit

Instructions for the use of Curtis Integrated Toolkit Software

Instructions to update Curtis Integrated Toolkit Software

Instructions to display and modify the parameters

Description of standard F4-A parameters

Description of standard ISS parameters

CDF file installation procedure

Replacement of the controllers

Replacement of the display

Replacement of the key switch

Replacement of the keypad (optional)

Replacement of the general emergency switch

Replacement of the horn

Replacement of the fuses

Replacement of the main contactor switch

Replacement of the fork lift cutout sensor

Replacement of the tiller sensor

Replacement of the tiller board

Replacement of tiller control springs

Replacement of tiller buttons

Replacement of the centred wheel sensor

Replacement of the battery charger (optional)

Replacement of the back-up alarm (optional)

Replacement of the DC/DC converter (optional)

Replacement of the working light (optional)

Replacement of the Pedestrian Awareness Light (optional)

Hydraulic functions

Hydraulic diagrams

Hydraulic diagrams for various functions

Hydraulic components

Dismantling of cartridge soilenoid valves

Removal of the initial lift cylinder

Removal of the cylinder head bushing

Hydraulic power unit removal

Hydraulic power unit disassembly

Identification of the master drive unit

Removal and disassembly of the reduction unit

Removal and replacement of the master drive unit assembly component

Braking System

Removal of the electromagnetic brake

Maintenance Warnings

Oils and Lubricants

Cleaning products

Scheduled Maintenance

Size: 56.6 MB

Format: PDF

Language: English

Brand: Hyster

Model: Hyster A3D9 P2.0S, P2.5S, P3.0S EU Service Manual 03.2022

Type of machine: Forklift Truck

Type of document: Service Manual

Content:

Important

General safety rules

Torque settings for screws nuts and fittings

Correct method for applying female fittings

Instruction for installing flexible hoses and fittings

Truck presentation

Views of the truck

Truck and load identification data

General specification

Traction wheel

Removal of the traction wheel

Torsion bar castor wheel assembly

Torsion bar castor wheel group disassembly

Replacement of the castor wheel torsion bar springs

Replacing the castor wheel

Replacing the castor wheel group

Load wheels

Replacing the tandem load wheel

Replacing the tandem load wheel assembly

Fixed linkage

Adjustable linkage

Removal of the linkage assembly

Key to tiller components

Tiller spring replacement

Adjustable steering spring replacement

Tiller removal

Replacement of the potentiometer and tiller base bearings

Replacement of the potentiometer and tiller base bearings of the adjustable steering

Key to scooter components

Scooter head removal

Scooter spring replacement

Replacement of the scooter control sensor and base bearings

Side gate replacement

Side gates microswitch replacement

Removal of the platform gas spring

Replacement of the platform touchless sensor

Removal of the platform

Replacement of the platform sensor

Traction motor

Motor dismantling

Steering motor

Steering motor dismantling

Forks chassis removal

Removal of the reduction unit

Disassembly of the reduction unit

Braking System

Removal of the electromagnetic brake

Before Installation

Truck assembly

Topping up the oil reservoir

Installation of the battery with vertical extraction

Installation of the battery with lateral extraction

Connection of cables to battery

List and description of the settings and adjustments to be carried out

Description of controller connectors

Device properties

Monitor menu

Troubleshooting

Warnings

Diagnosis system for F4-A Controller

Diagnosis system for Integrated Steering System

Electrical component measurements

Wiring diagrams

Electrical components

Identification of the tiller head controls and of the operator panel instruments

Display

Optional keypad

Instructions for the use of the new keypad application

Truck functions

Steering

Controller F4-A

Controller F1 - Si

Installation procedure of Curtis Integrated Toolkit

Instructions for the use of Curtis Integrated Toolkit Software

Instructions to update Curtis Integrated Toolkit Software

Instructions to display and modify the parameters

Description of standard F4-A parameters

Description of standard ISS parameters

CDF file installation procedure

Replacement of the controllers

Replacement of the display

Replacement of the key switch

Replacement of the keypad (optional)

Replacement of the general emergency switch

Replacement of the horn

Replacement of the fuses

Replacement of the main contactor switch

Replacement of the fork lift cutout sensor

Replacement of the tiller sensor

Replacement of the tiller board

Replacement of tiller control springs

Replacement of tiller buttons

Replacement of the centred wheel sensor

Replacement of the battery charger (optional)

Replacement of the back-up alarm (optional)

Replacement of the DC/DC converter (optional)

Replacement of the working light (optional)

Replacement of the Pedestrian Awareness Light (optional)

Hydraulic functions

Hydraulic diagrams

Hydraulic diagrams for various functions

Hydraulic components

Dismantling of cartridge soilenoid valves

Removal of the initial lift cylinder

Removal of the cylinder head bushing

Hydraulic power unit removal

Hydraulic power unit disassembly

Identification of the master drive unit

Removal and disassembly of the reduction unit

Removal and replacement of the master drive unit assembly component

Braking System

Removal of the electromagnetic brake

Maintenance Warnings

Oils and Lubricants

Cleaning products

Scheduled Maintenance

More the random threads same category:

- Hyster Forklift Parts and Service Manual CD7

- Hyster Forklift Parts and Service Manual CD2

- Hyster Forklift Parts and Service Manual CD3

- Hyster Forklift Diagrams and Schematics

- Hyster Forklift Parts and Service Manual CD4

- Hyster Forklift Parts and Service Manual CD10

- Hyster Forklift Parts and Service Manual CD1

- Hyster Forklift Parts and Service Manual CD9

- HYSTER Forklift H4.0 Shop Manual

- Hyster Forklift Parts and Service Manual CD6

- Hyster THREE-SPEED POWERSHIFT TRANSMISSION REPAIR Manual

- Hyster Forklift Parts and Service Manual CD5

- Hyster Forklift Parts and Service Manual CD8

- Linde Forklift 353-02D Operator Manual , SAFETY TIPS,Electric and Hydraulic circuit diagram

- Perkins Diesel Engines 1004-42(AR) 1006-60(YG) 1006-60T(YH) Repair And Maintenance Manual